- Coated Abrasives

- Bonded Abrasives

- Non-Woven Abrasives

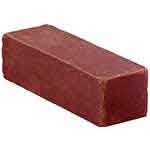

- Buffing and Polishing

- Wire Wheels and Brushes

- Cutting Tools

- Tools and Equipment

- Work Holding Systems

- Machinery

- Chemicals and Fluids

- Welding

- Safety Products

- Shop Accessories

- Top Manufacturers

ABRASIVE MATERIALS

CERAMIC ALUMINA PLUS

CERAMIC ALUMINA

‘’

ZIRCONIA ALUMINA

ALUMINUM OXIDE

‘’

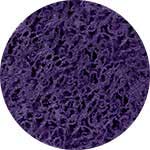

NON-WOVEN

‘’

CERAMIC ALUMINA WITH GRINDING AID & SELF SHARPENING ACTION

Ceramic flap discs run cooler than other abrasive grains because of their added grinding aid. While dissipating heat, it helps keep the disc cool, which prolongs the lifespan. On difficult-to-grind materials, ceramic grain should be the first choice as they are optimal for aggressive material removal. Ceramic flap discs have self sharpening grains which result in a consistent finish and provide steady, consistent sharp edges throughout the life of the disc. They run cooler than zirconia and aluminum oxide flap discs and reduce heat build up.

BEST USED ON: Hard-To-Grind materials; Soft Carbon Steel; Cast Iron

ZIRCONIA ALUMINA

This material grain is a mixture of Zirconia Dioxide and Aluminum Oxide. Zirconia Alumina is good for high stock removal applications and can be used on stainless steel and other challenging alloys. It can handle the heavier removal because of its reduced heat generation and continuous cutting edges with an additional lubricated layer. With the fuse of the two materials together, this creates a fine crystalline micro-structure that out-performs aluminum oxide.

BEST USED ON: Stainless Steel; Alloys; Aluminum

ZIRCONIA ALUMINA WITH DUAL ACTION GRINDING AIDS

Zirconia Alumina with Dual Grinding Aids has a high zirconia grain concentration with a specialty resin bond, which accounts for their superior performance. It is carbon based, which makes it versatile in removing stainless steel material. Zirconia Alumina with Dual Grinding Aids is a blend of Aluminum Oxide and Zirconia and the grinding aid helps break down the grains with light pressure. This heat-treated blend gives it double the cutting power of regular Aluminum Oxide. Another main feature of Zirconia Alumina with Dual Grinding Aids is that it is designed for applications that have a sensitivity to heat. Pigment is added to this material to give it its distinctive bright blue color. The unique fracturing properties of this material helps maintain consistent cuts. Zirconia Alumina with Dual Grinding Aids is specifically designed for superior work on stainless steel.

BEST USED ON: Heavy Duty Metals; Stainless Steel

ZIRCONIA ALUMINA WITH GRINDING AID

Our Zirconia Alumina material has a high Zirconia grain concentration with a specialty resin bond, which accounts for their superior performance. Our Zirconia products are manufactured with premium VSM materials. These products are specifically designed for fast cutting and superior work on stainless steel, alloys, and aluminum. Zirconia grains are designed for rapid stock removal and perform 25% better than conventional materials. They contain an added grinding aid for cool cutting, exceptionally long life and minimal heat discoloration of the material. Zirconia is designed for rapid stock removal on heavy duty applications and holds up well under high temperature and extreme pressures. The self-sharpening crystals leave steady, consistently sharp edges. It provides a good cut rate-to-cost ratio, giving cost efficiency. Less pressure is needed, and it still leaves a consistent finish with less operator fatigue. Zirconia grains are harder and wear more evenly than aluminum oxide, providing a longer cutting disc. It is best used on steel, stainless steel, and other metals. Contaminant-free, Iron Sulfer and Chlorine less than .1%.

BEST USED ON: Heat-Sensitive Alloys; Stainless Steel; Nickel Alloys; Titanium

ALUMINUM OXIDE WITH CALCIUM STEARATE LIQUEFYING AGENT

Aluminum Oxide Plus runs cool because of its added calcium stearate coating. This coating liquefies under heat which keeps the material cooler. The AO+ is specially designed for softer metals, specifically aluminum, as the coating will help prevent loading and glazing, which clogs the disc with swarf and possibly ruining your workpiece. It is also an excellent choice for blending stainless steel. It is contaminant-free, meaning iron, sulfur, and chlorine are less than .1% present.

BEST USED ON: Softer materials; Non-Ferrous materials; Aluminum; Bronze; Copper; Gold; Lead; Stainless Steel

ALUMINUM OXIDE

Aluminum Oxide grains are popular for universal use. This grain is a great choice for a wide range of materials.Aluminum Oxide is the most common and one of the earliest abrasives utilized in grinding wheels. Over the years, it has been used in combination with other materials to produce new abrasives that are now available today. It is cost efficient and a good basic level grain for general purpose applications.

BEST USED ON: Non-Ferrous materials; Aluminum; Brass; Copper; Zinc; Plastic; Wood; Alloyed & Unalloyed Steel; High Speed Steel; Carbon Steel; Stainless Steel; Cast Iron

SILICON CARBIDE

This is the hardest and sharpest of all the abrasive grains for the coated applications. Used in low-pressure applications, such as paint preparation, Silicon Carbide is a very fast cutting material that breaks down faster than Aluminum Oxide, leaving a fine finish.

BEST USED ON: Masonry; Composites; Ti-Alloys; Steel; Cast Iron; Tungsten Carbide; Aluminum & Non-Ferrous Metal; Plastic; Rubber; Glass; Marble

SURFACE CONDITIONING EXTRA COARSE

Surface Conditioning Discs are made of an open nylon web, impregnated with abrasive grains. They are excellent for blending scratches after the use of coated abrasives, weld cleaning and removing oxidation. They offer a continuous and controlled finish with minimal material removal. They will not give accidental gouges in your workpiece. They are safer to operate than a wire wheel or brush, as this will not have any chips flying off. It consists of a long life, high flexibility range, and a consistent finish while still having an aggressive performance. These discs condition, clean, and finish work piece and produce a brushed or lightly grained finish. Heavy Duty Ceramic discs are ideal for tougher applications when standard discs rip apart. They have up to 2 times life and are optimal for aggressive material removal. They run cooler and reduce heat build up. Aluminum Oxide (Coarse & Medium) abrasive material is popular for universal use and is used on a wide range of materials because of its versatility, toughness and value. Ultra fine is made of Silicon Carbide and is commonly used for low-pressure applications and is very sharp. It breaks down faster than aluminum oxide but has a superior finish.

BEST USED ON: Standard Duty - Ferrous & Non-Ferrous Metal, Stainless Steel. Heavy Duty - Ferrous & Non-Ferrous Metal, Steel, Stainless Steel.

SURFACE CONDITIONING COARSE

Surface Conditioning Discs are made of an open nylon web, impregnated with abrasive grains. They are excellent for blending scratches after the use of coated abrasives, weld cleaning and removing oxidation. They offer a continuous and controlled finish with minimal material removal. They will not give accidental gouges in your workpiece. They are safer to operate than a wire wheel or brush, as this will not have any chips flying off. It consists of a long life, high flexibility range, and a consistent finish while still having an aggressive performance. These discs condition, clean, and finish work piece and produce a brushed or lightly grained finish. Heavy Duty Ceramic discs are ideal for tougher applications when standard discs rip apart. They have up to 2 times life and are optimal for aggressive material removal. They run cooler and reduce heat build up. Aluminum Oxide (Coarse & Medium) abrasive material is popular for universal use and is used on a wide range of materials because of its versatility, toughness and value. Ultra fine is made of Silicon Carbide and is commonly used for low-pressure applications and is very sharp. It breaks down faster than aluminum oxide but has a superior finish.

BEST USED ON: Standard Duty - Ferrous & Non-Ferrous Metal, Stainless Steel. Heavy Duty - Ferrous & Non-Ferrous Metal, Steel, Stainless Steel.

SURFACE CONDITIONING MEDIUM

Surface Conditioning Discs are made of an open nylon web, impregnated with abrasive grains. They are excellent for blending scratches after the use of coated abrasives, weld cleaning and removing oxidation. They offer a continuous and controlled finish with minimal material removal. They will not give accidental gouges in your workpiece. They are safer to operate than a wire wheel or brush, as this will not have any chips flying off. It consists of a long life, high flexibility range, and a consistent finish while still having an aggressive performance. These discs condition, clean, and finish work piece and produce a brushed or lightly grained finish. Heavy Duty Ceramic discs are ideal for tougher applications when standard discs rip apart. They have up to 2 times life and are optimal for aggressive material removal. They run cooler and reduce heat build up. Aluminum Oxide (Coarse & Medium) abrasive material is popular for universal use and is used on a wide range of materials because of its versatility, toughness and value. Ultra fine is made of Silicon Carbide and is commonly used for low-pressure applications and is very sharp. It breaks down faster than aluminum oxide but has a superior finish.

BEST USED ON: Standard Duty - Ferrous & Non-Ferrous Metal, Stainless Steel. Heavy Duty - Ferrous & Non-Ferrous Metal, Steel, Stainless Steel.

SURFACE CONDITIONING FINE

Surface Conditioning Discs are made of an open nylon web, impregnated with abrasive grains. They are excellent for blending scratches after the use of coated abrasives, weld cleaning and removing oxidation. They offer a continuous and controlled finish with minimal material removal. They will not give accidental gouges in your workpiece. They are safer to operate than a wire wheel or brush, as this will not have any chips flying off. It consists of a long life, high flexibility range, and a consistent finish while still having an aggressive performance. These discs condition, clean, and finish work piece and produce a brushed or lightly grained finish. Heavy Duty Ceramic discs are ideal for tougher applications when standard discs rip apart. They have up to 2 times life and are optimal for aggressive material removal. They run cooler and reduce heat build up. Aluminum Oxide (Coarse & Medium) abrasive material is popular for universal use and is used on a wide range of materials because of its versatility, toughness and value. Ultra fine is made of Silicon Carbide and is commonly used for low-pressure applications and is very sharp. It breaks down faster than aluminum oxide but has a superior finish.

BEST USED ON: Standard Duty - Ferrous & Non-Ferrous Metal, Stainless Steel. Heavy Duty - Ferrous & Non-Ferrous Metal, Steel, Stainless Steel.

SURFACE CONDITIONING VERY FINE

Surface Conditioning Discs are made of an open nylon web, impregnated with abrasive grains. They are excellent for blending scratches after the use of coated abrasives, weld cleaning and removing oxidation. They offer a continuous and controlled finish with minimal material removal. They will not give accidental gouges in your workpiece. They are safer to operate than a wire wheel or brush, as this will not have any chips flying off. It consists of a long life, high flexibility range, and a consistent finish while still having an aggressive performance. These discs condition, clean, and finish work piece and produce a brushed or lightly grained finish. Heavy Duty Ceramic discs are ideal for tougher applications when standard discs rip apart. They have up to 2 times life and are optimal for aggressive material removal. They run cooler and reduce heat build up. Aluminum Oxide (Coarse & Medium) abrasive material is popular for universal use and is used on a wide range of materials because of its versatility, toughness and value. Ultra fine is made of Silicon Carbide and is commonly used for low-pressure applications and is very sharp. It breaks down faster than aluminum oxide but has a superior finish.

BEST USED ON: Standard Duty - Ferrous & Non-Ferrous Metal, Stainless Steel. Heavy Duty - Ferrous & Non-Ferrous Metal, Steel, Stainless Steel.

SURFACE CONDITIONING SUPER FINE

Surface Conditioning Discs are made of an open nylon web, impregnated with abrasive grains. They are excellent for blending scratches after the use of coated abrasives, weld cleaning and removing oxidation. They offer a continuous and controlled finish with minimal material removal. They will not give accidental gouges in your workpiece. They are safer to operate than a wire wheel or brush, as this will not have any chips flying off. It consists of a long life, high flexibility range, and a consistent finish while still having an aggressive performance. These discs condition, clean, and finish work piece and produce a brushed or lightly grained finish. Heavy Duty Ceramic discs are ideal for tougher applications when standard discs rip apart. They have up to 2 times life and are optimal for aggressive material removal. They run cooler and reduce heat build up. Aluminum Oxide (Coarse & Medium) abrasive material is popular for universal use and is used on a wide range of materials because of its versatility, toughness and value. Ultra fine is made of Silicon Carbide and is commonly used for low-pressure applications and is very sharp. It breaks down faster than aluminum oxide but has a superior finish.

BEST USED ON: Standard Duty - Ferrous & Non-Ferrous Metal, Stainless Steel. Heavy Duty - Ferrous & Non-Ferrous Metal, Steel, Stainless Steel.

SURFACE CONDITIONING ULTRA FINE

Surface Conditioning Discs are made of an open nylon web, impregnated with abrasive grains. They are excellent for blending scratches after the use of coated abrasives, weld cleaning and removing oxidation. They offer a continuous and controlled finish with minimal material removal. They will not give accidental gouges in your workpiece. They are safer to operate than a wire wheel or brush, as this will not have any chips flying off. It consists of a long life, high flexibility range, and a consistent finish while still having an aggressive performance. These discs condition, clean, and finish work piece and produce a brushed or lightly grained finish. Heavy Duty Ceramic discs are ideal for tougher applications when standard discs rip apart. They have up to 2 times life and are optimal for aggressive material removal. They run cooler and reduce heat build up. Aluminum Oxide (Coarse & Medium) abrasive material is popular for universal use and is used on a wide range of materials because of its versatility, toughness and value. Ultra fine is made of Silicon Carbide and is commonly used for low-pressure applications and is very sharp. It breaks down faster than aluminum oxide but has a superior finish.

BEST USED ON: Standard Duty - Ferrous & Non-Ferrous Metal, Stainless Steel. Heavy Duty - Ferrous & Non-Ferrous Metal, Steel, Stainless Steel.

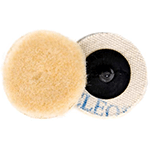

CLEAN & STRIP MAXIMUM PERFORMANCE

Clean & Strip-It discs are made with a polyamide fleece impregnated with an extra coarse grain of silicon carbide and then strengthened with a resin coating. The open-web structure allows heat to escape and run cooler, leaving no change in the workpiece’s shape or color. The open webbing also discourages loading, which preserves the life of the disc. The spring-like nature of the fibers respond to contours and effectively removes unwanted burrs, soils, and contaminants without gouging. This reduces extra time to rework the piece and boosts your productivity all around. Clean & Strip-It discs are safer than wire brushes because the discs are made from polyfibers, and this reduces the risk of creating flying metal chips which could potentially cause injury. Silicon carbide is sharper than other abrasive materials. When in use, the nylon fibers break down continuously, revealing fresh mineral for on-going, sharp cutting which wears evenly throughout its life.

BEST USED ON: Non-Ferrous Metals, Aluminum, Titanium, Stainless Steel, Steel, Fiberglass, Wood & Stone

CLEAN & STRIP ENHANCED PERFORMANCE

Clean & Strip-It discs are made with a polyamide fleece impregnated with an extra coarse grain of silicon carbide and then strengthened with a resin coating. The open-web structure allows heat to escape and run cooler, leaving no change in the workpiece’s shape or color. The open webbing also discourages loading, which preserves the life of the disc. The spring-like nature of the fibers respond to contours and effectively removes unwanted burrs, soils, and contaminants without gouging. This reduces extra time to rework the piece and boosts your productivity all around. Clean & Strip-It discs are safer than wire brushes because the discs are made from polyfibers, and this reduces the risk of creating flying metal chips which could potentially cause injury. Silicon carbide is sharper than other abrasive materials. When in use, the nylon fibers break down continuously, revealing fresh mineral for on-going, sharp cutting which wears evenly throughout its life.

BEST USED ON: Non-Ferrous Metals, Aluminum, Titanium, Stainless Steel, Steel, Fiberglass, Wood & Stone

CLEAN & STRIP STANDARD PERFORMANCE

Clean & Strip-It discs are made with a polyamide fleece impregnated with an extra coarse grain of silicon carbide and then strengthened with a resin coating. The open-web structure allows heat to escape and run cooler, leaving no change in the workpiece’s shape or color. The open webbing also discourages loading, which preserves the life of the disc. The spring-like nature of the fibers respond to contours and effectively removes unwanted burrs, soils, and contaminants without gouging. This reduces extra time to rework the piece and boosts your productivity all around. Clean & Strip-It discs are safer than wire brushes because the discs are made from polyfibers, and this reduces the risk of creating flying metal chips which could potentially cause injury. Silicon carbide is sharper than other abrasive materials. When in use, the nylon fibers break down continuously, revealing fresh mineral for on-going, sharp cutting which wears evenly throughout its life.

BEST USED ON: Non-Ferrous Metals, Aluminum, Titanium, Stainless Steel, Steel, Fiberglass, Wood & Stone

Below, you can view and download additional information from VSM Abrasives.

VSM Ceramic Grain

VSM Compact Grain

VSM Ceramic Coated Fact Sheet

VSM Technical Training Manual

Chat

Chat

Quote

Quote